The expansion of finishing options has been significant, offering clients greater flexibility, efficiency and creativity.

“Finishing” refers to the process of completing various finishing tasks directly to a printed item, without the need for separate post-press operations. Here are some notable areas of exciting “finishing” options for clients using offset printing:

Coating and Varnishing:

- In-line coating and varnishing units can apply coatings such as gloss, matte, or satin finishes directly onto printed materials. UV coating and aqueous coating options are available, enhancing the durability and visual appeal of printed products.

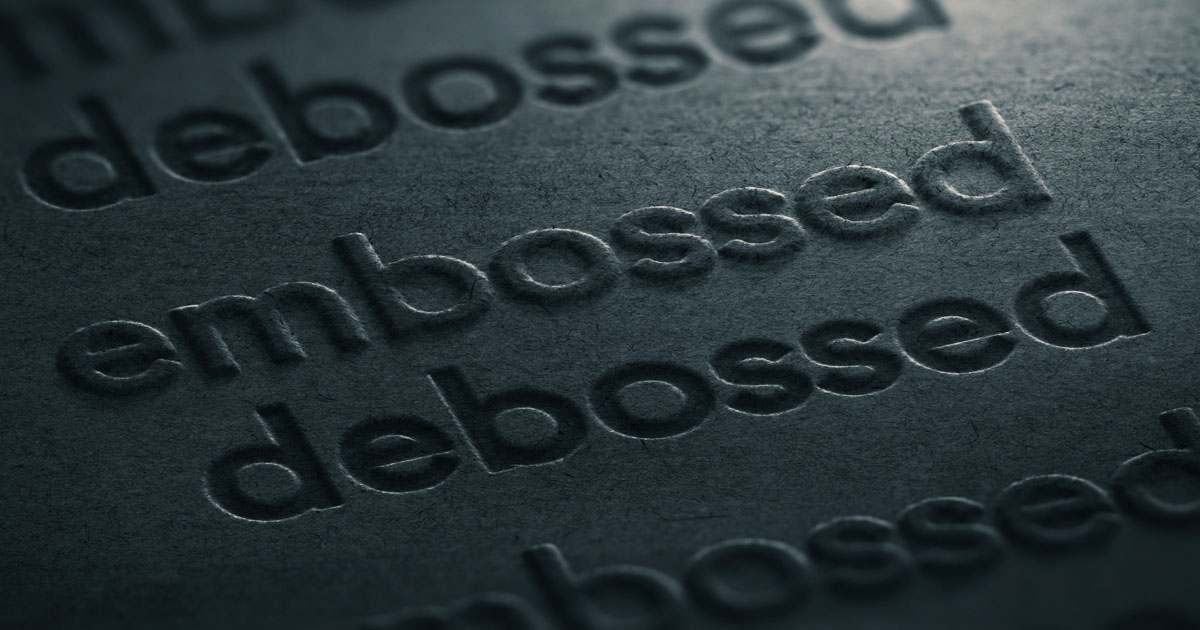

Embossing and Debossing:

- In-line embossing and debossing units can create raised or recessed textures on printed materials, adding a tactile element and enhancing visual interest. These techniques are often used for packaging, business cards, and specialty printed materials.

Die-cutting:

- In-line die-cutting units allow for the precise cutting of printed materials into custom shapes and designs. This capability is particularly useful for creating unique packaging designs and promotional materials.

Foil Stamping:

- In-line foil stamping units can apply metallic foil accents directly onto printed materials, adding a luxurious and eye-catching effect.

Foil stamping is commonly used for packaging, labels, and high-end marketing materials.

Perforation and Scoring:

- In-line perforation and scoring units can create perforated tear-off sections or score lines on printed materials, facilitating easy folding and tearing. This capability is essential for producing items such as tickets, coupons, and folded brochures.

UV Printing and Spot UV:

- In-line UV printing units can apply UV-cured inks directly onto printed materials, offering vibrant colours and enhanced durability.

Spot UV capabilities allow for the selective application of UV coating to specific areas of a printed piece, creating contrast and visual impact.

Folding and Binding:

- Some advanced offset presses include in-line folding and binding units, allowing for the creation of folded or bound products directly on the press. This capability streamlines production and reduces the need for separate finishing equipment.

Variable Data Printing (VDP):

- In-line VDP capabilities enable the integration of personalized data, such as names or addresses, directly into offset print runs.

This allows for the efficient production of customised marketing materials and direct mail campaigns.

Laminating:

- In-line laminating units can apply thin plastic films directly onto printed materials, offering protection and enhancing the appearance of the final product. This capability is commonly used for items such as ID cards, menus, and posters.

Integrated Quality Control:

- In-line inspection systems can detect and address print defects in real-time, ensuring consistent quality throughout the print run.

These systems use advanced imaging technology to identify issues such as colour variations, misregistration, and print defects.

Overall, the expansion of in-line finishing options for offset printing has transformed the capabilities of modern printing presses, allowing for the efficient production of high-quality, customized printed materials with a wide range of finishing effects. This integration of finishing processes directly into the printing press not only reduces production time and costs but also enables printers to offer their clients more creative and impactful print solutions.

EPM Print Group, as a long term, local Queensland business and market leading print solutions agency, can assist with brand management and growth right across Australia. If your business would like to be supported by a professional, reliable, cost effective business solution, reach out to our team at sales@epmprint.com.au

No comments yet.